Technology

Mild Dispersing

Ashizawa’s Original “Mild Dispersing” Technology

That Suppresses Damage to Particles

To grind and/or disperse particles down to the nanoscale, it is essential to minimize particle damage.

Ashizawa’s original technology, “Mild Dispersing,” enables dispersion while preserving the primary particles’ size, shape, crystal structure, and surface properties. Furthermore, by minimizing particle impact and surface activation, it effectively prevents re-agglomeration.

After Conventional Dispersing

Due to excessive dispersing, particles are susceptible to damage, resulting in re-agglomeration.

Over-dispersion may cause particle damage, which can result in re-agglomeration and degradation of their physical or chemical properties.

Mild Dispersing

Mild dispersing enables production of high quality and high-precision fine particles without excessive dispersing and damage.

Advantages of Mild Dispersing

- Maintained particle properties

- No re-agglomeration

- Reduce additives amount

Example of Mild Dispersing

Mild dispersing : Dispersing while maintaining the needle-like shape.

Case Example of TiO2

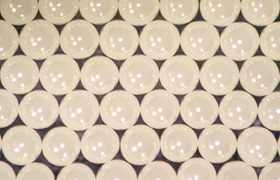

Ideal Beads’ Movement

”Spiral Laminar Flow“

Features of the MAX NANO GETTER HFM

The special agitator and rectification member form a spiral laminar flow, resulting in no dead space or congested points inside the grinding chamber. With this feature, beads are uniformly distributed, applying proper energy to particles and enabling effective dispersion.

Moreover, the MAX NANO GETTER HFM is a bead mill structured with a stirrer mechanism that facilitates self-dispersion by causing shear force and friction between particles in the slurry flow.

Points to Consider When Operating Conventional

Bead Mills While Suppressing Damage

1. Stable use of microbeads

In general, bead mills use beads ranging in diameter from 0.03 mm to 2.0 mm.However, for mild dispersion of nanoparticles, minute beads ranging from tens to around one hundred micrometers are used.

Using smaller beads increases the number of beads per unit volume, thereby raising the probability of contact between particles and beads.

Furthermore, since each bead has less mass, particles can be dispersed more gently, minimizing damage.

2. Reduction of the bead filling ratio

When using minute beads, it is preferable to reduce the bead filling ratio relative to the grinding chamber volume.While a lower bead filling ratio helps minimize particle damage, it may also reduce grinding efficiency.

3. Reduction of the agitator’s circumferential speed

Reducing the tip speed of the agitator can help suppress particle damage; however, it may also lead to a longer grinding time.

As described above, damage to particles can be reduced by operating machines under conditions 1 to 3. However, the use of minute beads may affect operability, and the reduction of the agitator’s circumferential speed and bead filling ratio may decrease efficiency.

To solve these issues, the NANO GETTER series has been developed and it enables “ideal mild dispersing.”